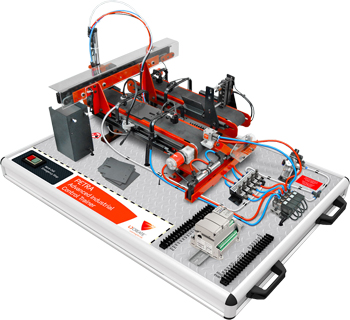

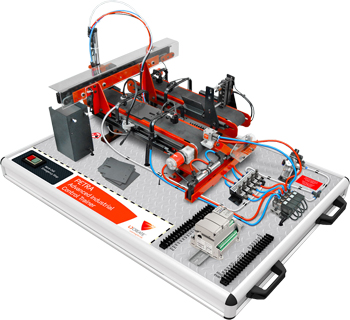

Advanced Industrial Control Trainer

Advanced Industrial Control Trainer provides students with a complete, simulated factory automation process that can be controlled from an industry-standard programmable logic controller (PLC).

The trainer is ideal for developing knowledge and skills in the areas of programmable controllers, engineering maintenance and condition monitoring techniques.

Students can use the trainer to develop and test PLC programs that:

- Move component parts along, and between, conveyor belts

- Control pneumatic actuators

- Monitor the outputs of a wide range of pneumatic and optoelectronic sensors

- Compare each part against its specification

- Reject non-conforming parts and accept parts that are within specification

An on-board DIN rail and screw terminal connectors allow the trainer to be used with a wide range of industry-standard PLCs (Allen Bradley MicroLogix 1200, Siemens Simatic S7-1200, Mitsubishi FX1S ...).

Typical Programming Activities include:

- Creating, downloading and running ladder logic programs

- Controlling the conveyor belts

- Controlling the pick-and-place plunger

- Controlling the gripper arm

- Monitoring parts and system sensors

- Latches

- Timers

- Counters

- Shift instructions

- Output sequencing

- Complete industrial control sequence

Trainer features:

- Two conveyor belts

- Parts dispenser

- Set of 15 parts - some inside, and some outside specification

- Pneumatic pick-and-place plunger

- Two-position pneumatically operated gripper arm

- Parts sensors (Pneumatic sensor measures part thickness, Opto-reflective sensor detects whether a slot is present, Optical sensors (6) detect holes in different positions and Opto-reflective sensors (2) detect and measure cut-out)

- System control sensors (Infra-red sensor indicates when parts dispenser is empty, Arm position sensor detects position of gripper arm, Plunger position sensor indicates vertical position of pick-and-place plunger and ‘Carriage in position’ sensor indicates when plunger carriage is in the requested position)

- Control inputs (Plunger vacuum, Plunger activate, Plunger carriage position (2), Conveyor belt activate (2), Gripper arm position and Gripper arm activate)

- On-board air pressure regulator

- Storage bins for separation of good and reject parts

- Expansion connector allows connection of additional sensors and actuators for student project work

- On-board +24V DC Power Supply

Trainer includes:

- Advanced Industrial Control Trainer

- 24V DC power adapter

- PLC connection leads

- User Manual

Product: Advanced Industrial Control Trainer

Product Code: 292-01