A typical automation task might involve controlling a conveyor belt via a PLC. Connection of the equipment components with bus systems has made electrical assembly child’s play. The new training system shows that configuration and planning in the TIA portal isn’t a problem either. The multimedia course uses practical experiments to guide the trainees through the basics of AS-i bus and PROFI NET. In the first step, they learn to control the conveyor belt via the PLC’s digital inputs and outputs. In the second step, the trainees plan all the bus systems shown, which involves them having to implement the right configurations in the TIA portal.

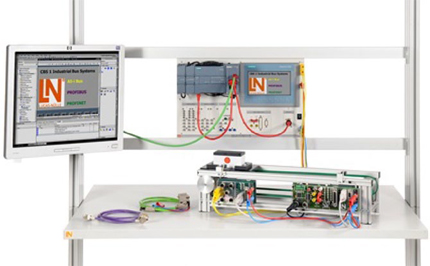

“The new equipment is compact yet covers a large amount of content. This allows all the important basics regarding bus systems to be conveyed and investigated while keeping the space requirement to a minimum,” explains Marijan Naglic, Product Manager for Automation Technology at Lucas-Nülle.

The students are required to work on smaller sub-projects for each bus system, which means that they acquire the expertise needed for larger projects in small steps. “This know-how is important for any student or trainee who wants to work with automation technology,” says Naglic.

With this set, you can learn about project planning for different bus systems and how they are used. Importantly, it is not only theoretical background but also the detailed experiment instructions which offer a thorough exploration of these bus systems. Students can start with direct communication via the I/O of a PLC system. A conveyor belt will then be connected to an AS-i bus to provide an introduction to bus systems in general. The bus system which is most widely used in industry, PROFIBUS, is dealt with second, while the concluding section is formed by a conveyor belt control system implemented in PROFINET. This means that a single system is controlled via multiple means of communication.

To learn more about automation training systems such as these and beyond, please contact Training Systems Australia on +613 9557 7993.